Lining with spirally wound pipes

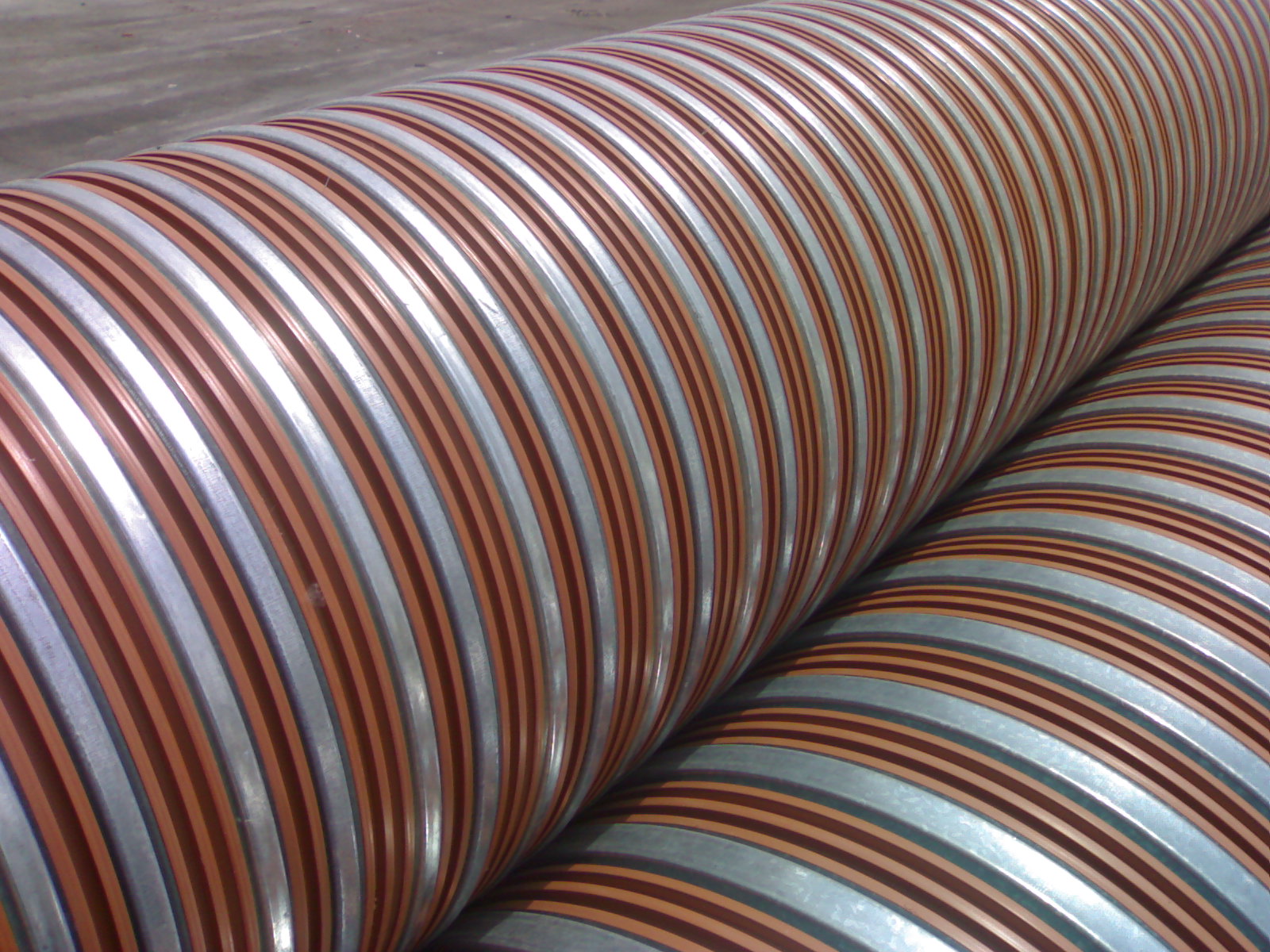

This method is based on the principle of an extruded plastic profile with high ring rigidity. PVC or PE-HD profiles are used and wound to form a new pipe using a winding machine. The edges of profile strips are connected positively and thus form a homogeneous and watertight piping system in the old pipe.

METHOD

The spiral-wound new pipe is designed as a self-supporting structure and, depending on the system, installed either without an annular gap as a close-fit system where the spirally wound pipe sits directly on the interior wall of the host pipe or with an annular gap, which is insulated afterwards.

With PVC-U profiles, the profile is wrapped using a mechanical lock with sealing and / or adhesive elements, and with PE profiles by using extrusion welding.

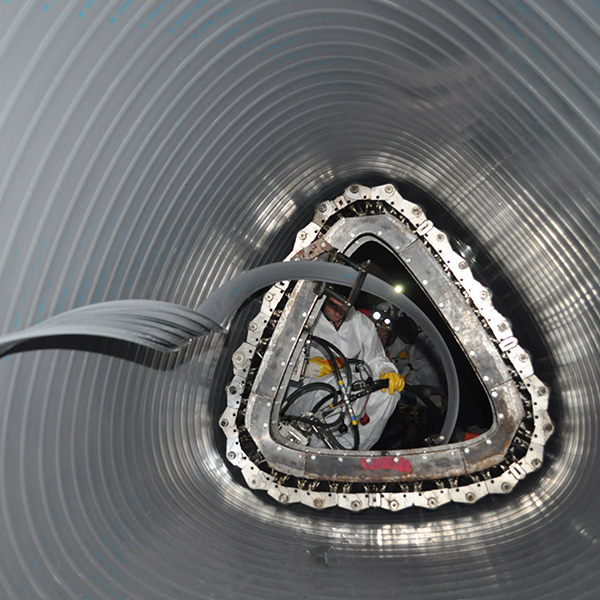

Depending on the system used, the winding machines are either installed inside the shaft or move through the pipeline system.

Spirally-wound-pipe with annular space

With the machine positioned in the shaft, the spirally wound pipe is wound into the host pipe with a smaller diameter than the old pipe. Then, depending on the static requirements, the annular gap is grouted with flowable filling mortar or a high-performance mortar.

Steel-reinforced spirally-wound-pipe with annular space

The spirally-wound-pipe is produced with steel-reinforced PVC profiles. This provides a structurally reinforced pipe with high inherent rigidity. depending on the static requirements, the annular gap is grouted with flowable filling mortar or a high-performance mortar after installation.

Close-Fit spirally-wound-pipe without annular space

The self-propelled wrapping machine forms a PVC-U profile strip into a wound pipe liner, which has a similar or better resistance than a newly installed PVC pipe. Thanks to the special winding machine it is possible to wind the liner close to the old pipe and thus produce a “close-fit” liner. This results in a highly resistant “pipe within a pipe” with minimal reduction in cross-section.

Expanda Method – without annular space

From the shaft, the wound pipe is initially wound into the existing pipe with a diameter smaller than the old pipe. The wound pipe is then fixed in the end shaft and the profile is rewound to expand the wound pipe which we call the Expanda Method. This system can thus do without an annular gap and tightly hugs the inner wall of the old pipe.

APPLICATION

Lining with spirally wound pipes is suited particularly for the rehabilitation of all sorts of circular pipes and special profiles as well as for large nominal diameters of up to 5,500 mm.

Especially small nominal widths can be rehabilitated quickly using the Expanda Method.

These methods are the only rehabilitation techniques worldwide where trenchless technology works for all pipe diameters.

Contact one of our partners near you

RTi unites under its umbrella seven building companies, with a large network of partners operating all over Europe, and our technology provider NordiTube. In case of queries, our team will be happy to assist you. We look forward to you hearing from you!