Cured-in-place (CIPP) lining for pressure pipes

While the CIPP method was originally used only for the rehabilitation of sewer pipes, RTi Rohrtechnik international group has adapted this technique also for use in municipal and industrial pressure pipes. Depending on host pipe conditions, static requirements and application areas, different liner systems are in use. We offer basic, semi-structural and fully structural systems.

Fully structural system (class A):

When a fully structural pipe liner is installed, all functions (including internal pressure absorption) are passed on to the liner.

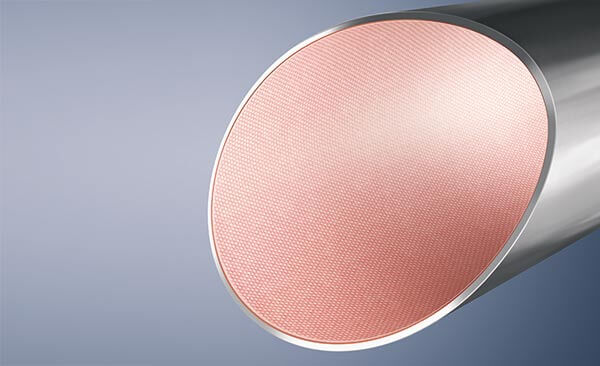

- Liner made of glass and felt layers

- High-quality epoxy resins optimised for compounding with glass fibre layers

- On-site impregnation

- Inversion or pull-in-place method

- Hot steam or water curing

- DN 150–1400 mm

Semi-structural system (class B):

Unlike basic liners, semi-structural liners are endowed with annular rigidity, which allows them to absorb external loads.

Basic liner (class C):

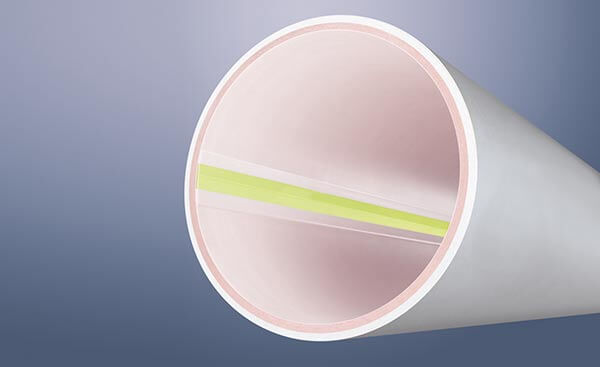

If the host pipe remains capable of bearing internal pressure and external loads, it can be rehabilitated by installing a thinner, interactive liner. This allows to repair leaks, improves the hydraulic properties and provides lasting protection against corrosion.

- Round woven textile liner with PE, Hytrel or TPU coating

- Optionally with resin carrier mat

- High-quality epoxy resins with excellent adhesion and flexibility

- On-site impregnation

- Inversion method

- Hot steam or water curing

- DN 80–1200 mm

| Application | Water, gas, oil, sewage, industry, special applications | |

| Nominal width | (mm) | 80-1400 |

| Pressure range | Up to PN 30, depending on system | |

| Wall thickness after curing | (mm) | 3-21 |

| Resins employed | Epoxy resin | |

| Coating | PE, PP-PE copolymer, TPU or Hytrel (depending on medium) | |

| Host pipe material | For every type of material | |

| Maximum rehabilitation length | (m) | 500 (depending on size and wall thickness) |

| Terminal integration for pressure pipes | Standard solutions such as liner end rings | |

| Connection technology | r.tec® coupling, standard fittings | |

| Classification AWWA M28 | (Class) | 2, 3, 4 |

| Classification EN ISO 11295 | (Class) | A, B, C |

Contact one of our partners near you

RTi unites under its umbrella seven building companies, with a large network of partners operating all over Europe, and our technology provider NordiTube. In case of queries, our team will be happy to assist you. We look forward to you hearing from you!