PIPE REHABILITATION UDPATE

IN THE LAST FEW MONTHS SEVERAL DEVELOPMENTS HAVE BEEN REALZIED SUCCESSFULLY BY RTi

Altenberg – May 2017

INNOVATION –

AN INTEGRAL PART OF RTi ROHRTECHNIK GROUP

New developments and advancements in pipe rehabilitation technology play an essential role for RTi Rohrtechnik Group in catering to customer needs and setting trends in the pipe rehabilitation industry. RTi’s mission is to develop products that revolutionise the pipe rehabilitation market. And these products are inspired by our customers!

Thanks to the achievements of our experienced team at NordiTube, RTi’s global production and trading company, we are able to guarantee a high level of quality in our systems and to launch innovative developments.

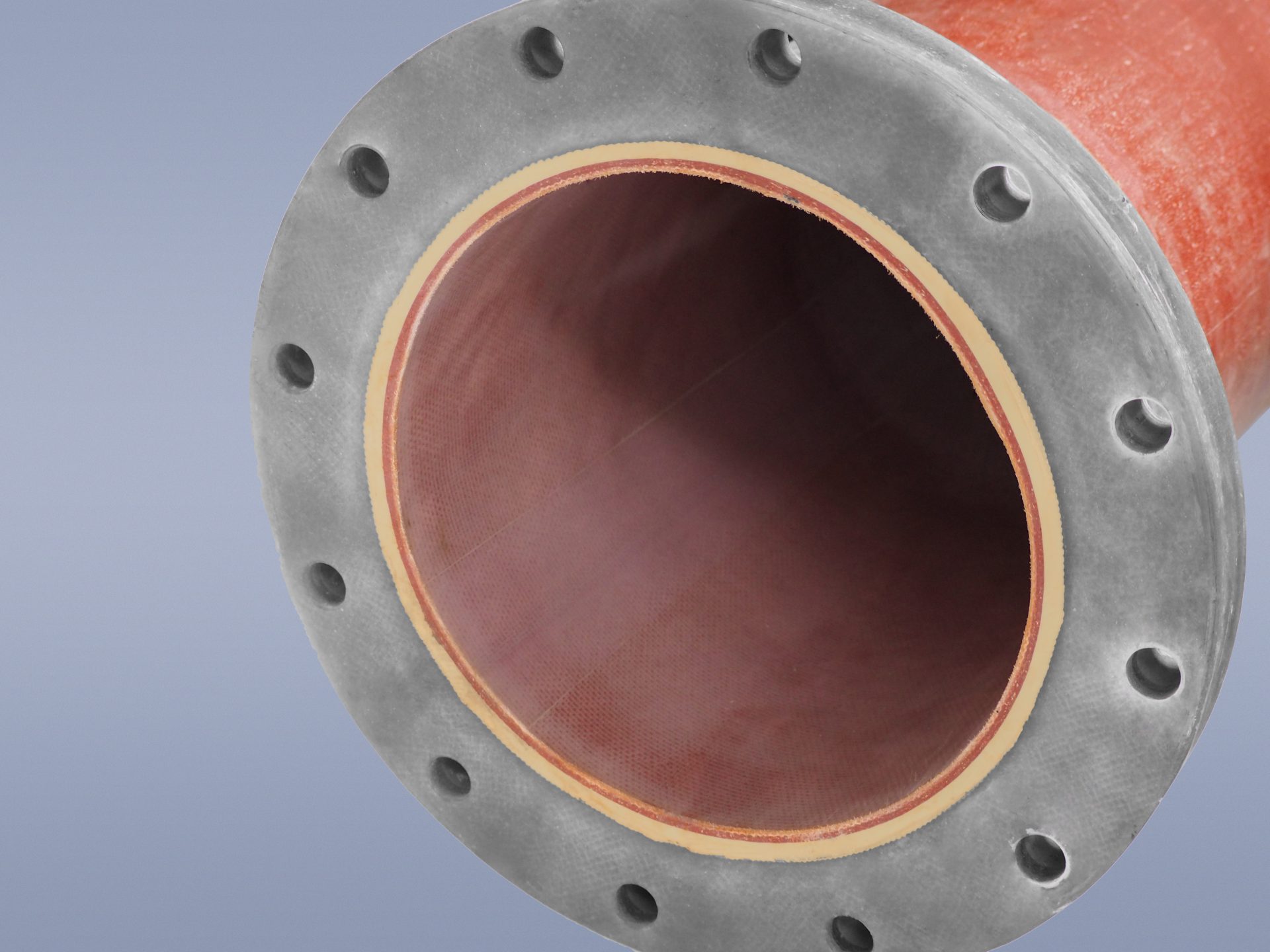

TUBETEX GRP –

DISCOVER A NEW APPROACH TO TRENCHLESS PIPE REHABILITATION FOR PRESSURE PIPES

Current liner systems for pressure pipes are mostly designed as “class A” (full load-bearing capacity) or “class C” (interactive with adhesive) in conformity with ISO 11295. Such systems therefore have to be adjusted for “class B” use (interactive with circular rigidity), which in most cases turns out to be uneconomical and complicated.

NordiTube has therefore developed TUBETEX GRP, a liner for “class B” use in conformity with ISO 11295. This is a truly semi-structural liner with circular rigidity and specifically designed for pressure pipe rehabilitation projects with “class B” requirements (semi-structural, interactive, with cirular rigidity).

The innovative approach chosen by NordiTube is to combine the TUBETEX fabric liner, which has been successfully used in practice for 30 years, with special glass fibre reinforced plastics to create the TUBETEX GRP liner. The glass fibre layer has been optimised to fit in with the pull-in-place or inversion method; wall thickness may be adjusted to the specific requirements. With this product, we are able to offer our partners a custom-made low-cost liner for pressure pipes which is tailored to individual customer needs.

With TUBETEX GRP it is also possible to connect a special flange directly with the liner. The new pipe is connected quickly, easily and independently from the host pipe.

TUBETEX GRP is NordiTube’s economical “class B” liner product suited for use in drinking-water applications and in pressure lines ranging from DN 200 to DN 1000 mm and operating at pressures of up to 16 bar. The new liner enables the system operator to rehabilitate his system in an accurate, economical and high-quality manner.

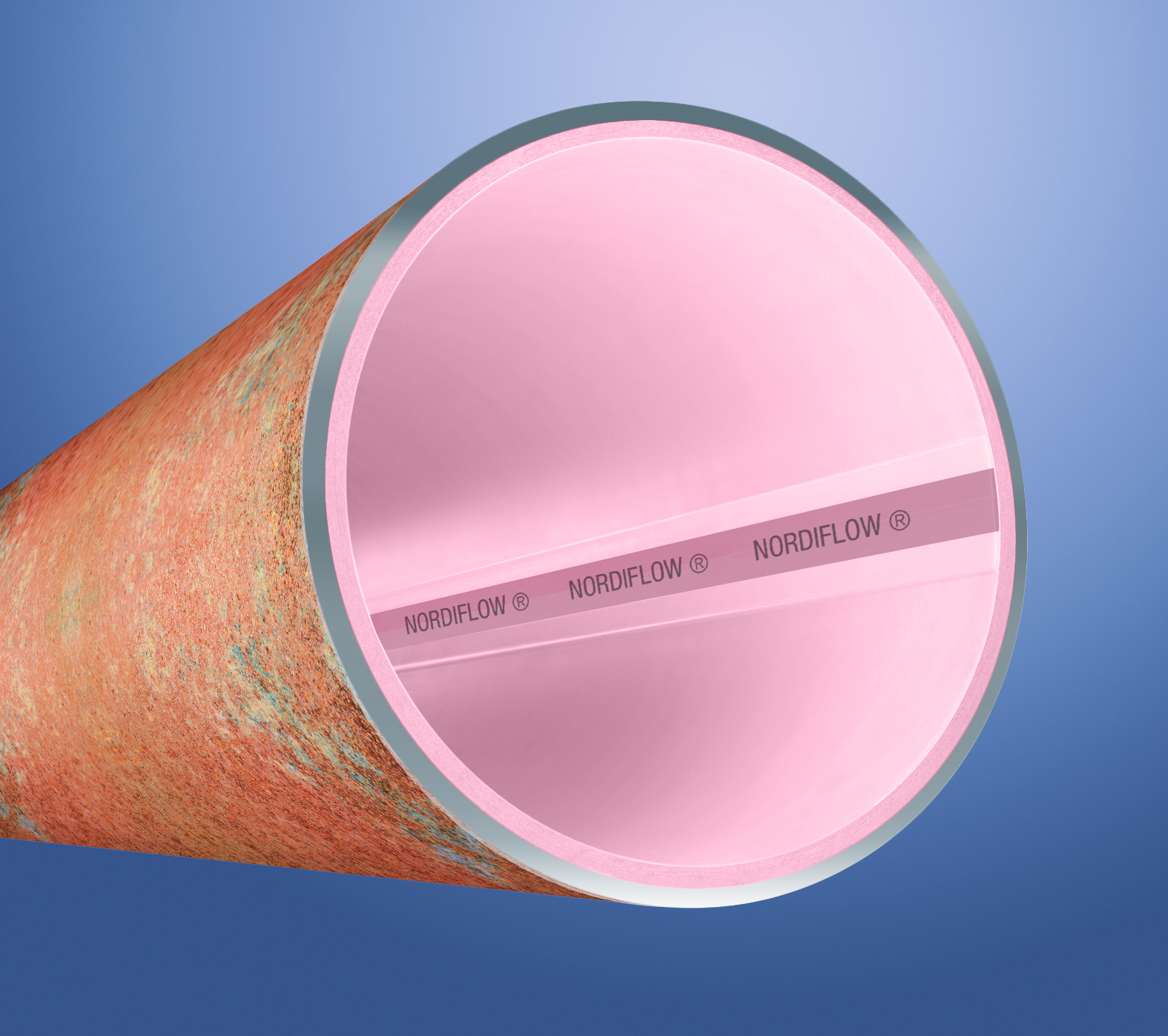

NORDIFLOW –

THE EASY INVERSION METHOD

The NORDIPIPE PE pull-in liner is a load-bearing “class A” liner system which has been successfully applied in practice for many years, but is not suited for inversion techniques.

NordiTube has therefore launched a new development on the market: NORDIFLOW, a glass-fibre-reinforced liner specially designed for inversion techniques. NORDIFLOW basically differs from the NORDIPIPE PE pull-in liner in its structural properties while meeting the same requirements as a load-bearing “class A” liner. The new system enables pipefitters to rehabilitate pipes ranging from DN 150 to 1200 mm in size.

This product is also used in combination with NordiTube’s newly developed connecting technology, which facilitates a quick and easy connection directly with the liner, independently from the host pipe.

NORDIFLOW has successfully passed all individual tests in terms of mechanical parameters and suitability for drinking water applications. A full-scale capability test in accordance with ISO 11297-4, which is currently in its trial phase, will be available in future.

NORDIWALL HT –

HIGH-TEMPERATURE LINER FOR INDUSTRIAL APPLICATIONS

To date, there has been no economical CIPP system for industrial use to rehabilitate pipes which are resistant to temperatures exceeding 100°C.

NordiTube has successfully developed a CIPP system which is based on the proven NORDIWALL FLEX needle felt liner: NORDIWALL HT. This new rehabilitation technology allows system operators for the first time to rehabilitate pipes exposed to high temperatures.

Thanks to its modified PP coating and its specially developed resin system, the NORDIWALL HT liner will resist temperatures of up to 140°C.

NORDIWALL HT is the economical choice for high-temperature pipe rehabilitation projects. After a successfully completed test phase, the excellent quality of this liner has been validated in a variety of industrial projects, particularly on offshore oil platforms.

PROJECT AT GERMANY’S LARGEST LANDFILL: RTI GERMANY INVESTS IN A NEW HIGH-EFFICIENCY RINSE-AND-SUCTION VEHICLE

In autumn 2016, RTi Germany GmbH made an investment and purchased a specialty vehicle for high-pressure cleaning of leachate drainage pipes at landfills and municipal transport lines. The high-efficiency equipment allows operators to perform high-pressure cleaning operations in pipes which are up to 1000 metres in length with no intermediate shafts. A high-performance vacuum unit additionally allows to accomplish suction heights of up to 30 metres.

RTi Germany successfully applied this specialised technology for the first time at Germany’s largest landfill, the Ihlenberg landfill located in Mecklenburg-Western Pomerania. The project was executed by RTi Germany’s team of experts, who boast a long track record of successful landfill projects.

The drainage pipes, up to 600 metres in length, were partly covered with extremely hard incrustations. Despite their hardness, the sediments could be succesfully removed by using a high-efficiency turbine nozzle, powered by two parallel high-pressure pumps of the landfill rinsing unit, while being gentle on the drainage pipes and preserving their hydraulic functionality. The success of the special cleaning job was documented by an explosion-protected 600 m TV unit.

RTI AT RO-KA-TECH

RTi Rohrtechnik will present at Ro-Ka-Tech, the international tradeshow for pipe, sewer and industrial services to be held from 10 to 12 May 2017. Visit RTi in Hall 5, Booth H5 B02 and learn more about our range of services and technologies related to inspection, cleaning and trenchless pipe rehabilitation and renewal. The RTi team will be happy to share information about the latest developments and ongoing projects with you. The pipe rehabilitation specialist is looking forward to meeting you in Hall 5, Booth H5 B02!

MANY YEARS OF KNOW-HOW –

30+ YEARS OF EXPERIENCE IN TRENCHLESS PIPE REHABILITATION

RTi Rohrtechnik international has its head office in Austria and unites under its umbrella seven construction companies, with an extensive network of subsidiaries operating across Europe, as well as the global production and trading company NordiTube with its own liner production in Belgium.

RTi boasts a success record of 35 years in the inspection and trenchless rehabilitation of all types of piping systems, including wastewater, drinking water, gas and oil pipes.

The service portfolio of RTi Rohrtechnik Group comprises all standard technologies used for trenchless inspection, cleaning, repair and rehabilitation of all types of pipes as well as new pipe installations, container/tank rehabilitation, sanitary engineering and landfill construction services. This allows us to provide the perfect solution to any problem related to defective gravity and pressure conduits ranging from DN 80 to 5500 mm in size.